We wish to thank The Model Engineer, Nexus Special Interests Ltd., for permission to reproduce the following article, originally published in the Model Engineer.

|

CONVERTING SHAPER

Sir, In the correspondence that takes place from time to time on shaper versus milling machine for the model engineer's workshop, I cannot remember to have seen the prime advantage of the small power shaper mentioned -its ready conversion to a power hacksaw. Whatever our circumstances may be, most of us have crowded workshops; even if we could pay for it, to introduce another machine might not be physically possible without rebuilding. It certainly would not be my own case! I enclose a picture of the machine-shop end of my own workshop. There is not even room to install the drilling machine at right angles to the bench, yet everything is convenient and to hand. The Adept No 2 power shaper is driven by a long belt from the countershaft of the Myford Super-Seven lathe, the installation of another motor being difficult and perhaps unnecessary. One can't work on two machines at once. |

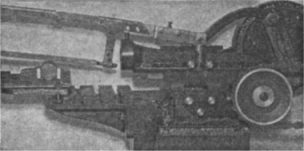

The second photograph shows the simplicity of the hacksaw conversion. The clapper head is removed. A bolt turned from 1 in. square section steel is fitted permanently in the position of the operating spindle of the hand-shaper before it was converted to power, secured from rotating by a taper pin. Through the square head of this permanent bolt is drilled and reamed a 3/8 in. hole to take a horizontal bolt on which the driving arm pivots, provided with a bearing 3/4 in. long with a bronze bush and oil hole. The driving arm is made from the discarded handle of the hand-shaper. The hacksaw frame is one that had a wooden handle, discarded when someone gave me a more modern hacksaw. |

| Right: Two aspects of the workshop of Nevil Shute of Victoria, Australia |

|

|

The weights on the other end are change wheels, discarded when I got the gearbox for the Super-Seven. The speed is about 100 strokes a minute and the thing saws as straight as I can, which isn't saying much. The error in straightness is about 1/16 in. in a cut 1 1/4 in. deep. But the labour that it saves! The conversion from shaper to hacksaw takes about two minutes, and vice versa. The total cost of this power hacksaw was about 1s. 6d. for bolts. |

| MODEL ENGINEER |